A mechanical part used to convey a unidirectional power through a unidirectional stroke. Its applications can be found in cranes, constructional sorts of gear, hydraulic presses, and numerous modern kinds of hardware.

It comprises of a round and hollow barrel to contain cylinder pressure and produced using sharpened cylinders, a cylinder top which works in encasing the weight chamber toward one side, a cylinder head which works in encasing the opposite finish of the weight chamber, a cylinder inside the barrel used to isolate the weight zones, a cylinder pole which is appended to the cylinder and stretches out from the cylinder through the bar end head, a seal organ which is a region among bar and head where seals are put to forestall spillage, seals which are intended for various applications and prerequisite, and some different parts.

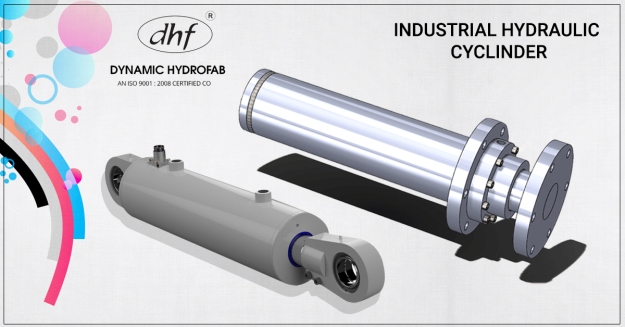

Industrial Hydraulic Cylinders get their capacity from pressurized hydraulic liquid, which is commonly oil. The hydraulic cylinder comprises a cylinder barrel, in which a cylinder associated with a cylinder pole moves to and fro. The barrel is shut toward one side by the cylinder base (likewise called the top) and the opposite end by the cylinder head (additionally called the organ) where the cylinder pole comes out of the cylinder. The cylinder has sliding rings and seals. The cylinder partitions within the cylinder into two chambers, the base chamber (top end) and the cylinder pole side chamber (bar end/head end). These cylinders can be purchased from Industrial Hydraulic Cylinder Suppliers.

Spines, trunnions, clevises, and hauls are normal cylinder mounting choices. The cylinder pole likewise has mounting connections to interface the cylinder to the article or machine part that it is pushing or pulling.

The “generator” side of the hydraulic framework is the hydraulic siphon which conveys a fixed or directed progression of oil to the hydraulic cylinder, to move the cylinder. The cylinder pushes the oil in the other chamber back to the repository. On the off chance that we expect that the oil enters from the top end, during augmentation stroke, and the oil pressure in the bar end/head end is around zero, the power F on the cylinder pole rises to the weight P in the cylinder times the cylinder territory A

There are essentially two sorts of the plan which incorporate Tie pole cylinder and Welded body cylinder.

Tie pole style Industrial Hydraulic Cylinders India utilizes high quality strung steel poles to hold the two end tops to the cylinder barrel. They are regularly observed in mechanical plant applications. Little bore cylinders normally have 4 tie poles, and huge bore cylinders may require upwards of 16 or 20 bind poles so as to hold the end tops under the colossal powers created. Tie bar-style cylinders can be totally dismantled for administration and fix, and they are not generally adaptable.

Welded body cylinders have no tie bars. The barrel is welded straightforwardly to the end tops. The ports are welded to the barrel. The front pole organ is generally strung into or darted to the cylinder barrel. That permits the cylinder pole to get together and the bar seals to be evacuated for administration. Welded body cylinders have various points of interest over tie bar style cylinders. Welded cylinders have a smaller body and regularly a shorter by and large length empowering them to fit better into the tight limits of the hardware. Welded cylinders don’t experience the ill effects of disappointment because of tie bar stretch at high weights and long strokes. The welded structure likewise fits customization. Exceptional highlights are handily added to the cylinder body, including uncommon ports, custom mounts, valve manifolds, etc.

There are some extraordinary sorts of developments including Telescopic cylinder, Plunger cylinder and Differential cylinder.

The length of hydraulic cylinders is the aggregate of the stroke, the thickness of the cylinder, the thickness of base and head and the length of the associations. Regularly this length doesn’t fit in the machine. All things considered, the cylinder bar is additionally utilized as a cylinder barrel and a second cylinder pole is utilized. These sorts of cylinders are called adaptive cylinders. On the off chance that we call an ordinary bar cylinder single-stage, adjustable cylinders are multi-stage units of two, three, four, five or more stages. By and large adaptive cylinders are considerably more costly than ordinary cylinders. Most adaptive cylinders are single acting (push). Twofold acting adaptive cylinders must be exceptionally planned and produced.

A hydraulic cylinder without a cylinder or with a cylinder without seals is known as an unclogger cylinder. An unclogger cylinder must be utilized as a pushing cylinder; the most extreme power is cylinder pole region increased by pressure. This implies an unclogger cylinder when all is said in done has a moderately thick cylinder bar. These cylinders can be purchased from Industrial Hydraulic Cylinder manufacturers

A differential cylinder acts like a typical cylinder when pulling. On the off chance that the cylinder anyway needs to push, the oil from the cylinder pole side of the cylinder doesn’t come back to the store, yet goes to the base side of the cylinder. In such a manner, the cylinder goes a lot quicker, however, the most extreme power the cylinder can give resembles an unclogger cylinder. A differential cylinder can be fabricated like a typical cylinder, and just an extraordinary control is included. The above differential cylinder is likewise called a regenerative cylinder control circuit. This term implies that the cylinder is a solitary bar, twofold acting hydraulic cylinder. The control circuit incorporates a valve and funneling which during the expansion of the cylinder, directs the oil from the pole side of the cylinder to the opposite side of the cylinder rather than to the siphon’s supply. The oil which is led to the opposite side of the cylinder is alluded to as the regenerative oil.